- Ovens

- Provers

- Spiral mixers

- Planetary mixers

- Hydraulic dividers

- Bun rounding dividers

- Fermenters

- Baguette molders

- Water preparation

- Volumetric dividers

- Conical roll forming machines

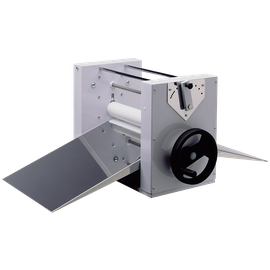

- Dough sheeters

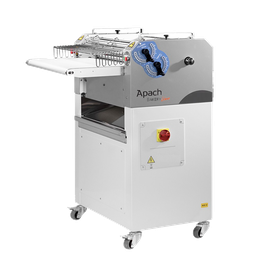

- Bread slicers

- Bread mill

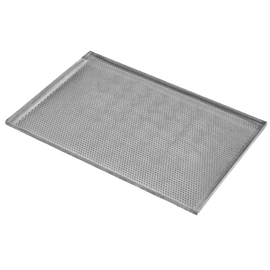

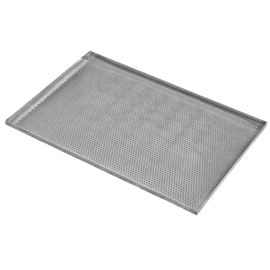

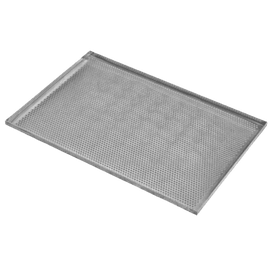

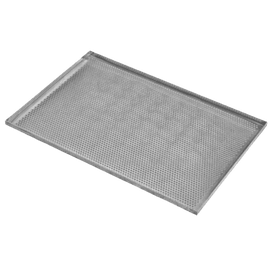

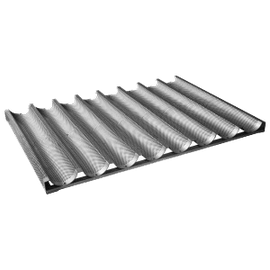

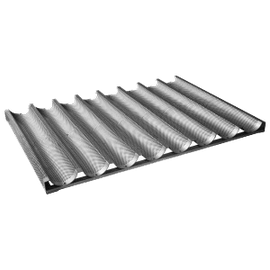

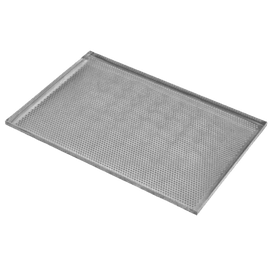

- Baking trays

- With conveyor belt

- With prerounding system

- With premoulding system

- Accessories for divider

- Rotary ovens

- Deck ovens

- Mini-rotary ovens

- Convection ovens

- Spiral mixers with fixed bowl

- Spiral mixers with removable bowl

- Bowl tilting

- Double arm mixers

- APL series

- Accessories for planetary mixers APL

- Automatic

- Semi-automatic

- Manual

- Automatic

- Semi-automatic

- Manual

- M series

- M TOUCH series

- MBA series

- -

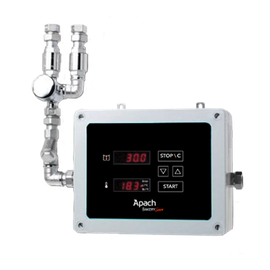

- Water chillers

- Doser-mixers

- F series

- ASH series

- Accessories for dough sheeters ASH

- G42 series

- C42S series

- CP42S series

- MI52 series

- MAC100 series

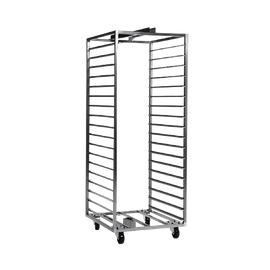

- Provers

- Retard provers

- Intermediate provers

- 60х40

- 60х80

- 50х70

- Catalog

- Video

- News

- Dealers

- Contacts