If you decide to open a mini-bakery, be sure to think over all the nuances: from the entrance group and interior to the range of bakery products. It is known that baking bread is a complex process that consists of several stages. For everything to be really tasty, it is not enough just the skilled skills of the staff. Equipment also plays a huge role.

Apach Bakery Line will not only help you select equipment for each stage of production, but also design your bakery! For this, the team has prepared comprehensive solutions. At the warehouse, you will find special ready-made kits suitable for specific requests, the expected volume of products and the characteristics of the premises. The productivity of the offered machines is up to 350 kg per shift.

One of the main stages is dough preparation, which includes dosing of recipe components, kneading and fermentation. The dosing of raw materials is carried out by appropriate devices that measure and send the required quantities of water, flour and other recipe components to the kneading machine.

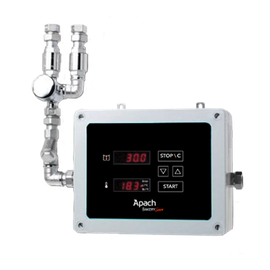

- - WATER MIXER APACH BAKERY LINE DOX 25M - MAX inlet temperature 65 degrees, dosing accuracy ± 1%, 2 digital displays show the quantity and temperature, the temperature is measured by a built-in sensor, complete with a hose for supplying water to the bowl, a body made of ABS plastic;

- - SPIRAL DOUGH KEEPER APACH BAKERY LINE V60 - bowl volume 80 l, 2 motors, 2 speeds, 2 optional electro-mechanical timers / electronic buttons with system bypass selector, bowl reverse;

The next step is dough cutting - dividing into pieces of a given weight, molding and final proofing of dough pieces.

- - SEMI-AUTOMATIC DIVIDER-ROUNDER APACH BAKERY LINE SPA SA30 - 4 kg capacity, 30 pieces of dough 40-135g each, 3600 pieces / h, bowls and aluminum alloy heads, hard anodized, 304 stainless steel knives and grates, food grade PE inside;

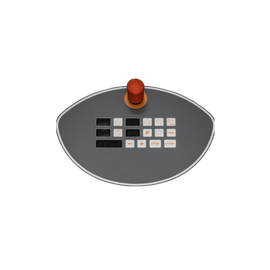

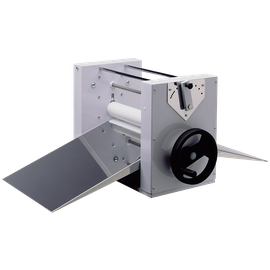

- - APACH BAKERY LINE ASH500 / 1000 TEST ROLLER - floor, roll thickness 0.1-34mm, roll diameter 60mm, conveyor 488x1000mm, handle width 120mm , 1 speed, joystick;

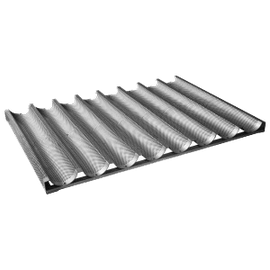

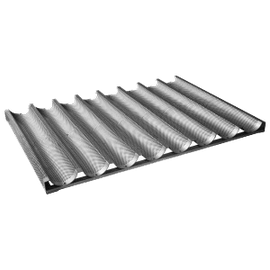

- - BAGUETTE MOLDER APACH BAKERY LINE MBA / 3C - 3 adjustable rollers providing a high degree of accuracy, dough volume 50-2000g, distance between cylinders 0-20mm , quick belt change without disassembling the machine, made of painted steel;

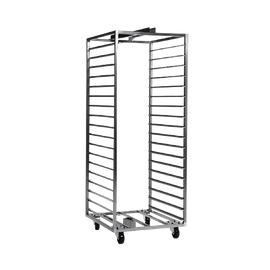

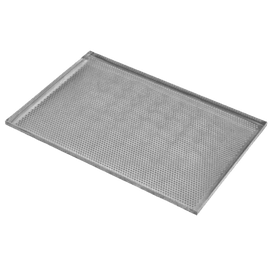

- - APACH BAKERY LINE AR FLP60401P CABINET WITH DISTANCE INTERRUPTION - for 60x40 sheets (19 pieces), operating temperature ranges from -5 to +35 degrees, electric air heating, defrosting, condenser works up to 43 degrees of ambient, rounded corners inside for better cleaning and maintenance, all stainless steel finishing.

The most important stage is baking. It is very important to choose the most suitable oven depending on the type of product and the desired output.

- - ROTARY ELECTRIC FURNACE APACH BAKERY LINE B46E DP - for sheets 40x60cm, digital control panel, hook, reduced blowing speed, manual steam valve, visor with extractor hood, supplied in 2 modules, chamber and front panels made of stainless steel + TROLLEY FOR ROTARY OVENS APACH BAKERY LINE SERIES B46 15 LEVELS AISI 430.

The end of the technological process is the cooling and storage of products.

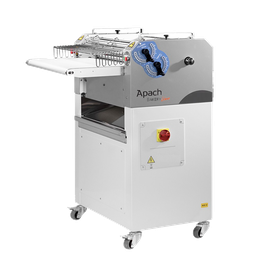

- - BAKERY TABLE MANUAL APACH BAKERY LINE G42 - normal cutting width 420mm, blade pitch 11 mm, tabletop model of equipment for general use with manual cutting mode + BASE BA420 FOR G42 SERIES APACH BAKERY LINE BREAD CUTTERS.

For the manufacture of not only bread, but also confectionery we offer:

- - PLANETARY MIXER APACH BAKERY LINE APL40 3F. - bowl 40 l, 1.5 kW, 380V, 35-150 (100-420) rpm, floor-standing.

The entire range of mixers and dough rollers is also available.

We have presented a basic assortment for a small bakery. There are special discounts for sets of equipment!